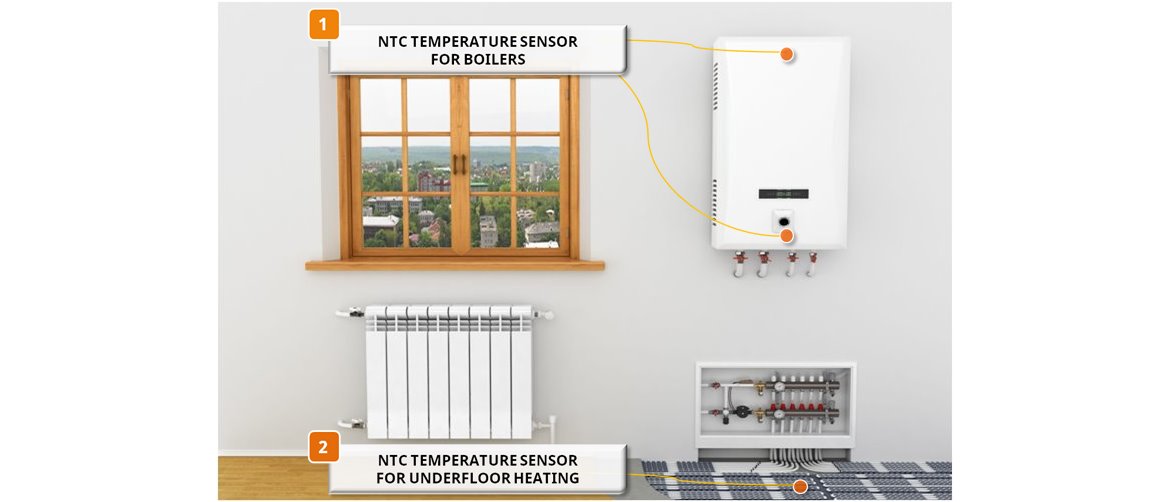

Product Application

Central heating that consists of a boiler and radiators is one of the most common heating systems used in Europe and the U.S. for houses that do not have district heating. Boiler supplies space heating, domestic hot water, or both. To ensure users safety, comfort and heating efficiency, NTC temperature sensors in the boiler measures water temperature or combustion temperature for best heating control. Temperature sensors usually are placed at different points in boilers detecting temperature of flow and return pipes, of domestic hot water outlet, and of flue gas. THINKING offers NTC temperature sensors with various mounting features to fit different boiler and heating system application requirements.

for Boilers

THINKING offers a series of immersion type temperature sensors that are suitable for direct contact in the water flow or flue gases. The immersion type sensors can meet various temperature measurement and installation requirements while sharing the same benefits of accurate temperature detection, fast thermal response (thermal time constant < 3 s) , corrosion resistance, and long-term stability. They can be used to measure either water or flue gas temperature to help the controller to increase the heat or to lower temperature.

(a) Short thermal response time in water and easy to screw-in design make the NTC temperature sensor an ideal solution for pipe fluid temperature detection and control. The temperature sensor assembled in a nickel plated brass cap with a G 1/8'' thread, washer and connector, is easy to install.

(b) The small-diameter sensing top design optimizes the response time and is ideal for detecting flue gases in gas boiler. The NTC temperature sensor is assembled in a 316 stainless steel housing with a thread, O-ring and connector for fast and simple installation.

(c) The NTC temperature sensor reponds fast to temperature change and comes with push-fit mounting design, which offers an installation alternative to screw-in design.

(d) With bullet-type NTC temperature sensor mechanical design, the sensor responds relatively fast (< 2 seconds), and helps power energy saving. The fast response sensor is perfect for detecting water temperature in gas combi boiler and instant water heater to ensure user safety during hot shower. The sensor can be customized with various mounting features such as brass nut or clip to best fit your mounting requirement.

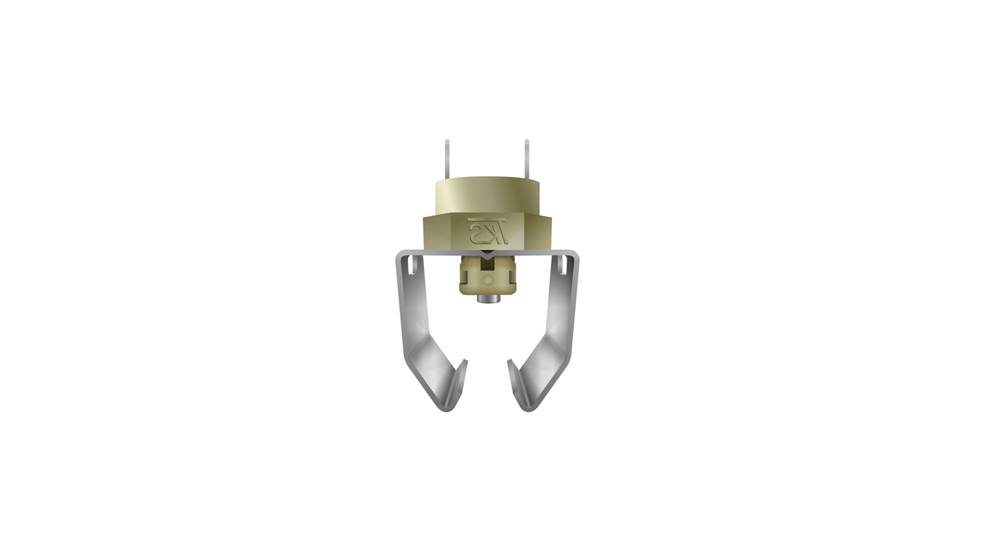

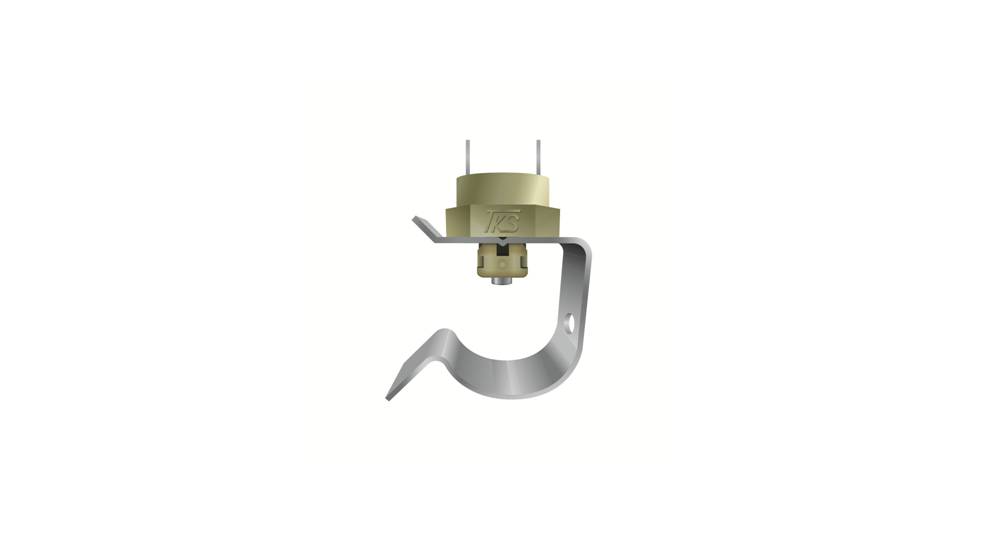

To measure the temperature of flow and return pipes, THINKING recommends the patented clip-on surface mounting temperature sensor with high moisture resistance and high accuracy. The NTC sensor placed in the tip of a small diameter brass housing enables thermal coupling to the metal pipe and thus improves response time (< 2s). The rugged spring clip is very easy to install and it allows the sensor to be secured easily to pipes. The clips can be applied to pipes with diameters of 13, 15, 18, 22, and 28 mm. The sensor is aviailable in two types of clips to meet different installation requirement.

for Boiler

The NTC temperature sensor is assembled in a 316 stainless steel housing with heat-resistant lead wire that allows the sensor to withstand a high temperature of 250°C. It responds fast to temperature fluctuation and is ideal for measuring flue gas temperature. The flange design allows simple and stable screw-on installation.

for Underfloor Heating

For houses that incorporate hydronic underfloor heating, the water is heated to a warm temperature from the boiler and circulates in a set of plastic pipes. A temperature sensor is usually mounted under the floor surface to help control the room temperature. We recommend the use of epoxy coating type NTC temperature sensor with lead wire because it is double insulated and resists to moisture. The lengths of the cable can be customized to fit the application specification.

‧

In addition to temperature sensors, THINKING offers a broad line of circuit protection components to protect the latest appliances. Click here to see circuit protection recommendations for home appliances.

‧ Most temperature sensor types can be delivered in various shapes and with a wide choice of casing materials, cable lengths, connectors, terminals and mounting features to meet different application needs. Alternative resistances tolerances, R/T characteristics, resistance ratings, and UL recognized models are available on request. Please contact us to learn more about temperature sensors.